DECK LEDGER TO RIM JOIST

CONNECTION DETAILS

The LedgerLOK Ledger Board Fastener has been designed specifically for attaching the deck ledger to a rim joist or band board of the house in a code compliant manner. When installed as instructed in this bulletin, the LedgerLOK can be used to replace the 1⁄2″ Lag Screws called for in Chapter 5 of the International Residential Code (IRC).

In addition, the proprietary coating on this fastener exceeds the corrosion protection provided by code approved hot-dipped galvanized coatings.

INSTALLATION PROCEDURES

- Choose 3 — 5⁄8 “ or 5” LedgerLOK so that threads fully engage the rim material and fastener tip extends beyond the inside face of the rim joist

- Use a high torque, 1⁄2″ variable speed drill (18V if cordless)

- Follow the minimum spacing and fastening patterns from Figure 1 and Table 1

- Install fasteners through the ledger and sheathing. Continue in to the rim joist until the washer head is drawn firm and flush

- to the ledger board. Do not overdrive.

CORROSION STATEMENT

The proprietary galvanized and polymer coating applied to the LedgerLOK has been tested under the current ICC standard for evaluating corrosion resistance in treated lumber (AC257) and deemed suitable alternative to code-approved hot-dipped galvanized coatings when exposed to ground contact ACQ preservative treatment in wet-use conditions. A statement of this compliance can be found in the ICC Evaluation Report for LedgerLOK (ESR #1078), available online at icc-es.org or the FastenMaster website.

For applications within 1,000 feet of saltwater, we recommend the use of a stainless steel fastener.

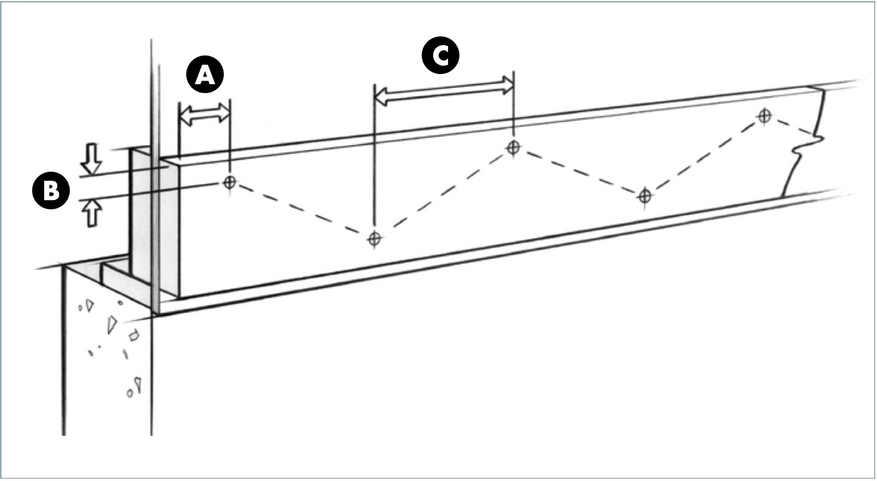

SPACING REQUIREMENTS

Fasteners should be staggered in a “V” pattern and spaced as follows:

- Minimum end distance = 3 – 3⁄4″

- Minimum edge distance = 2″

- On-center spacing = Per Table 1

FASTENING PATTERN

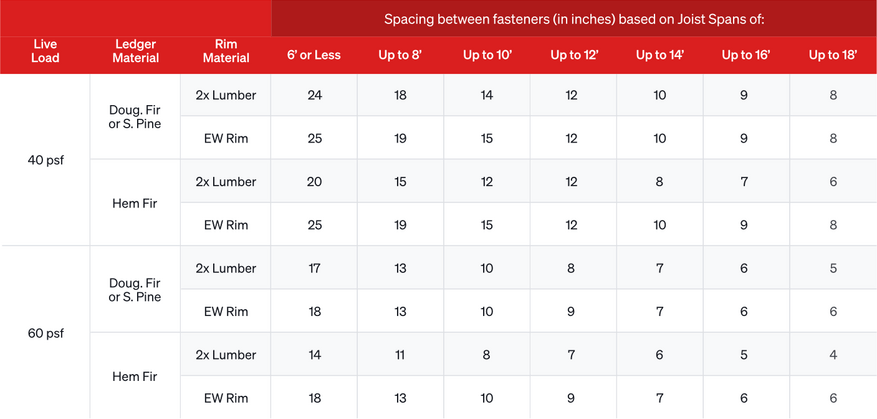

Determine the proper spacing of LedgerLOK fasteners from Table 1 below based on:

- Live load requirement for your local code

- Ledger material being attached to the house

- Rim material that you are attaching to

- Joist span as measured from the ledger to the first supporting beam

LedgerLOK fastening patterns outlined in this table provide equal or better performance to lag screw patterns in the 2009, 2012 and 2015 IRC in accordance with IRC sections R104.11 and in accordance with generally accepted engineering practice. Design values used to create these patterns were derived from individual fastener testing under ICC Acceptance Criteria AC233 (ESR #1078) as well as full system testing directly comparing lag screw and LedgerLOK performance in ledger to rim connections using generally accepted industry standards used to generate the IRC fastener spacing tables for lag screws.

- Ledger materials must be a minimum of 2×8 no minal dimensional pressure-preservative-treated No.2 lumber from any of the following species: Hem-Fir, SPF, Douglas Fir or Southern Pine

- Rim joist materials must be either solid sawn 2x lumber or engineered wood specifically designated by the manufacturer as rim material. 2x lumber may be of any species greater than 0.42 specific gravity, including SPF, HF or DF. Engineered Wood (EW) Rim may be OSB, LSL or LVL material measuring 1″ or greater in thickness

- Sheating of 15⁄32″ or 7⁄16″ OSB may separate the ledger and rim but must be attached per code. For additional materials between ledger and rim, please refer to the guidelines below.

Wet service conditions have been tested for and applied to the patterns above. No further reductions for wet service need to be applied..

The code-standard dead load for building materials of 10 pounds per square foot is assumed in all calculations above.

As required by IRC Section 507.2.1, the calculations and installation instructions found in this bulletin have been reviewed and found to be in accordance with accepted engineering practices. For a copy of the engineer stamped/sealed letter or further technical information to support this bulletin, please contact FastenMaster at 800.518.3569.

GENERAL FASTENING GUIDELINES

- The LedgerLOK is not designed for attachment to masonry/concrete or over stucco, siding, rigid foam insulation or brick veneer

- Connection sand joints shall be properly flashed to prevent water from contacting the rim joist

- Where a positive connection to the rim joist cannot be verified through inspection, decks shall be self-supporting.

- Ledgers should not be attached over cantilevered portions of the house where the rim is unsupported by a foundation.

- For ledgers being attached to open web floor trusses, consult ‘Attachment of Residential Deck Ledger to Metal Plate. Connected Wood Truss Floor System” published by the Structural Building Component Association for proper design methods. This Technical Note can be found at www.sbcindustry.com

- Under the following conditions, the LedgerLOK may still be approved, but a design professional should be consulted.

Proper spacing requirements:

In areas where live load requirements exceed 60 psf or snow load requirements exceed 70 psf

For decks designed to carry increased dead loads (ex: hot tubs, stationary planters)

Three-season or fully enclosed decks supporting an overhead roof.

All local code requirements as well as guidelines set for thin this technical bulletin must be followed for patterns outlined above to be applicable.

JOIN THOUSANDS OF PROS

New product news, giveaways and everything else about FastenMaster and our products