Ask a contractor or DIYer if they prefer nails vs. screws, and you’ll get a different answer every time. Everyone has a favorite, but there are better times to use nails vs. screws. Let’s run through the various applications and opportunities to use both.

Nails vs. Screws: What’s the Difference?

Both nails and screws have their purpose, but for a long time, nails were selected over screws on projects because they were quicker to fasten in place.

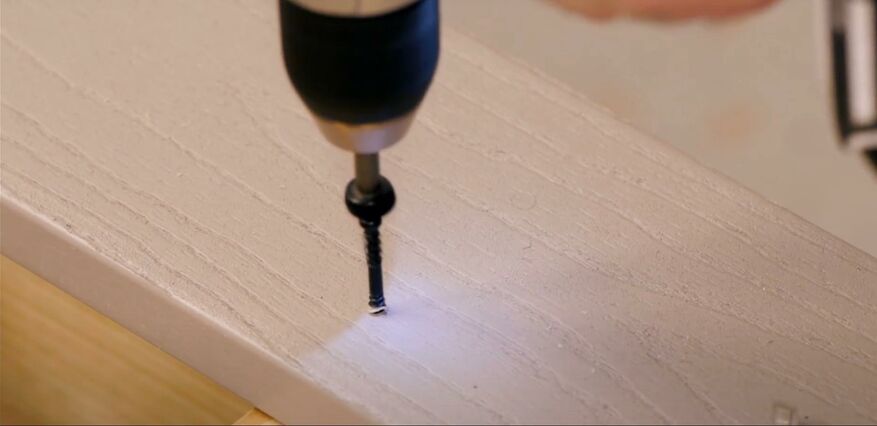

However, advancements made in tool technology changed all of this. “As electric and pneumatic screwdrivers became more commonplace, the popularity of screws grew exponentially,” according to Popular Mechanics. “But the real quantum leap for power-driving screws coincided with the introduction of the cordless drill/driver, the most popular portable power tool ever invented.”