Roof truss installation can be one of the most dangerous parts of the home building process. Collapses from improperly braced trusses can result in disaster. Despite this, many builders are either unaware or simply overlook the need to adequately brace the roof structure during construction.

Builders often rely on their personal experience, resulting in a false sense of security that can have catastrophic consequences. Just because someone is used to doing things a certain way, this does not necessarily mean it is the right way.

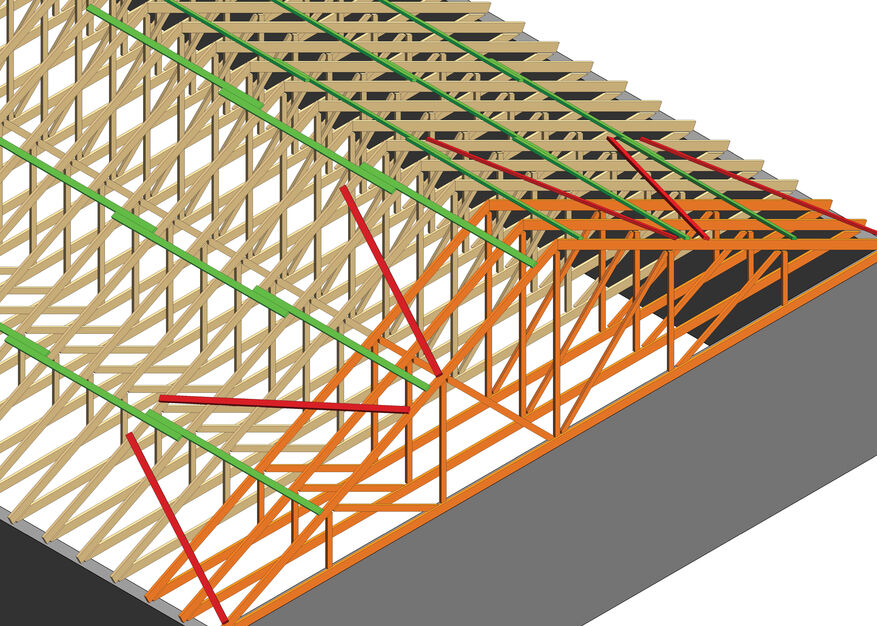

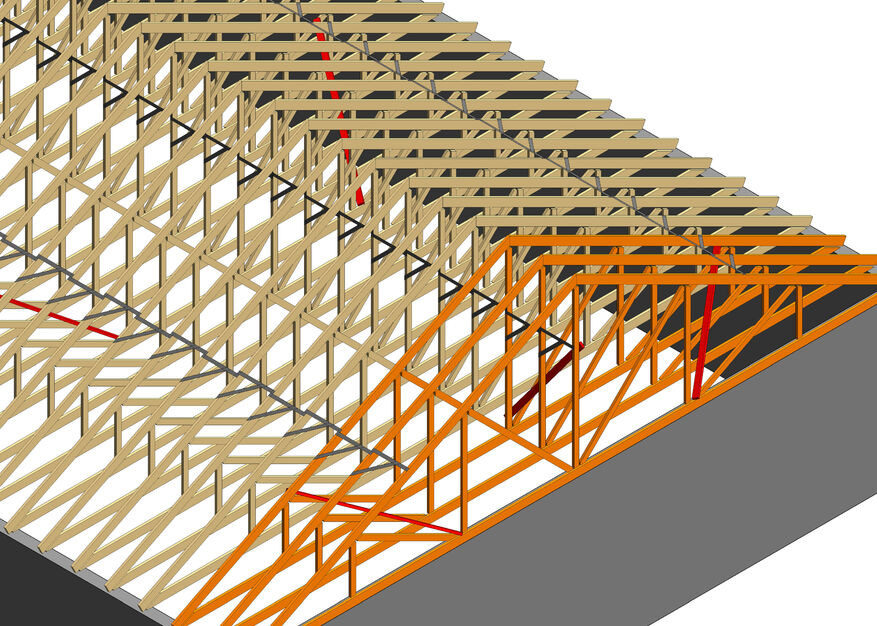

There are multiple ways to safely secure a roof truss set. Regardless of the bracing method, it’s always important to follow the truss manufacturer’s instructions, as well as industry best practices when it comes to setting and bracing trusses.