Fastening PVC Trim Correctly

Before you start the installation, load up your kit with the right tools and materials. Make sure you’re using high-quality screws that will not succumb to breakage. Use a screw system that is hard to strip out and has a high level of holding power, especially when using it for larger trim boards.

When starting the installation, secure your fastening system. This ensures the trim boards will not move when the outside temperature fluctuates with the changing seasons. Just as if you were cutting wood, your tools should be similar, excluding the fasteners.

We recommend only using carbide-tipped blades, but combination saw blades will work, too. If you use plain steel blades, they’ll dull quickly. If you’re cutting your PVC trim on-site and not using factory edges, we suggest you plan your project around the idea that your cut edges will be hidden since it makes for a cleaner finish. If there are any extra rough edges, you can sand it down with an orbital sander armed with 100-grit paper. A belt sander may melt the PVC as it is plastic, so be careful.

Just like with wood, create overlapping 45-degree joints in areas where the ends of trim meet. Cut the first piece of trim to fall just past the center of the stud so the overlapping piece can be securely fastened to the stud center. Apply cement to both trim pieces before you fully secure them to the wall.

If you’re installing trim in temperatures that hit higher than 80 degrees, you can fit joints tightly. If it gets cold where you’re installing, leave a gap for potential expansion and contraction. Between 60 and 80 degrees, the standard guideline is a 1÷16” gap for every 18 ft. of length. Below 60 degrees, you should leave a ⅛” gap. Read the fine print of your manufacturer manual to ensure the best accuracy in your gaps. You can seal the gap with paintable acrylic or polyurethane caulk.

From there, you can begin the fastening process. Select the right screws, which we’ll detail in the next section. Fastening well with the right screws helps with expansion and contraction. Make sure you fasten to framing, never just into the sheathing. Select fastener lengths that will be able to penetrate the framing by at least 1 ½”. You should place fasteners approximately every 16” at both edges of the trim, with spacing ½” from the edges. If your trim is 10” or wider, add one more fastener in the middle. For 16” wide trim, you should utilize four screws every 16”.

Best Screws for PVC Trim

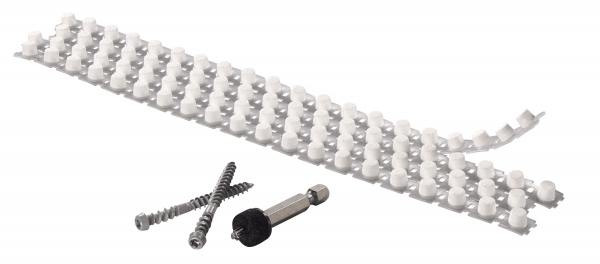

The best screws for PVC trim come from Cortex. They come in a kit that includes a bit, plugs and screws. All you do is drill the screw through the trim. Once the desired depth is reached, the bit will completely stop the screw. Set the drill down, tap the plug in the hole, and your project is complete!

Cortex Hidden Fastening System for PVC